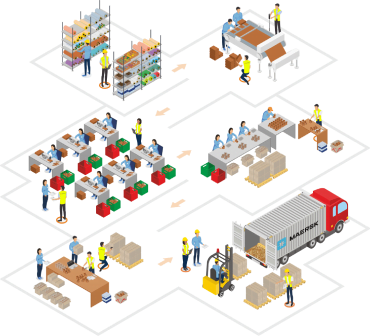

Bottles and jars, available in glass and plastic, are essential products used in various industries such as cosmetics, food and beverage, and pharmaceuticals. Quality and user experience are crucial factors to consider when sourcing these products. While Asian manufacturing countries like China and India offer competitive prices, there are potential quality risks. Thorough Quality Control and Due Diligence are vital to ensure product reliability and safety. Buyers must prioritize inspections, lab testing, and supplier audits to mitigate any quality issues. By focusing on these aspects, businesses can confidently source bottles and jars from Asia while maintaining high standards.