In today’s world, traceability audits are more than just a regulatory requirement—they’re the key component in building trust, improving quality, and staying competitive. When every raw material, component, and finished product is accurately tracked, you gain complete visibility into your operations. This not only ensures compliance but also strengthens your ability to respond to challenges, such as customer complaints or potential recalls.

With the right traceability systems in place, you can optimize processes, mitigate risks, and secure a strong position in your industry. And in this article, we’ll show you exactly how to do that.

Keep reading.

What is Traceability in Manufacturing?

Traceability in manufacturing refers to the ability to track and trace the journey of raw materials, components, and finished goods throughout the production and supply chain. This process ensures that every step in the manufacturing process is documented, from sourcing raw materials to delivering finished products to customers.

The purpose of traceability is multifaceted. It enables manufacturers to identify the origin of materials, monitor production efficiency, and address quality issues promptly. Additionally, traceability systems provide a detailed record that helps businesses comply with industry regulations and international standards, such as ISO 9001.

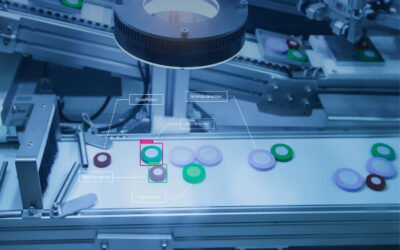

Traceability systems often rely on technologies like RFID tags, barcode scanning, and data analytics to track products accurately. These tools offer real-time visibility into production processes, inventory management, and supply chain activities, making it easier to ensure compliance and maintain high production quality.

What are the Main Perspectives of Traceability?

Traceability in manufacturing can be understood from several perspectives. Each perspective focuses on a specific aspect of tracking and monitoring within the production and supply chain. These perspectives include chain traceability, internal traceability, forward traceability, and backward traceability.

Chain Traceability

Chain traceability refers to the ability to track products as they move forward and backward through the supply chain. This approach provides manufacturers with a comprehensive view of their operations, enabling them to trace a product’s journey from raw materials to the end consumer and vice versa.

Forward traceability ensures that manufacturers can track the movement of finished goods to distributors, retailers, and ultimately, customers. On the other hand, backward traceability allows businesses to trace the origins of a particular product or component to identify potential issues in raw material sourcing or earlier stages of production.

Internal Traceability

Internal traceability focuses on tracking materials, components, and processes within a specific manufacturing facility or segment of the supply chain. It ensures that every stage of the production process is documented, allowing manufacturers to pinpoint quality issues or inefficiencies that occur on the shop floor.

For instance, by using traceability software integrated with RFID tags or barcode scanning, you can monitor inventory movement and identify defective products before they leave the production line. This level of detail is crucial for maintaining production quality and ensuring compliance with industry regulations. Internal traceability also supports continuous improvement by highlighting areas where production efficiency can be enhanced.

Forward Traceability

Forward traceability ensures that products are tracked as they move from the manufacturing process to the end-user. This perspective is vital for delivering high-quality finished goods to the market while gathering valuable insights about customer interactions.

With forward traceability, you can track products through distribution channels, identify where they are sold, and even monitor returns. This level of visibility requires robust traceability systems, such as digitized tracking methods and retailer collaboration, to provide real-time information. By understanding how and where your products are being used, you can improve traceability efforts and optimize customer satisfaction.

Backward Traceability

Backward traceability focuses on tracing a product’s history from its final state back to its origin. This approach is especially useful in industries like food manufacturing, where contaminated products need to be traced to their source for recall purposes.

For example, if a defective batch of finished products is identified, backward traceability allows you to determine which raw materials or processes contributed to the issue. This insight enables you to address root causes and prevent similar problems in the future. By implementing a backward traceability system, you can also ensure compliance with international standards and regulatory requirements.

Manufacturing industries that deal with critical components, such as the automotive industry, rely heavily on backward traceability to safeguard production quality and maintain accountability across their operations.

End-to-End Traceability

End-to-end traceability combines the principles of internal, forward, and backward traceability to create a comprehensive tracking system. This approach provides manufacturers with complete visibility across the entire supply chain, from sourcing raw materials to delivering finished goods.

With end-to-end traceability, you can identify quality issues at any stage, ensure regulatory compliance, and maintain detailed records related to all aspects of the production process. It also enables businesses to achieve real-time visibility into their operations, making it a powerful tool for improving compliance, reducing waste, and driving continuous improvement.

Supplier Mapping

Supplier mapping focuses on collecting and organizing data about your suppliers, their material sources, and their production processes. This level of traceability is critical for ensuring that all raw materials used in manufacturing meet quality and compliance standards.

By implementing supplier mapping, you can track the origin of raw materials and ensure that your suppliers adhere to agreed-upon standards. This process often involves maintaining records related to certifications, production line audits, and quality checks conducted at supplier facilities. Supplier mapping provides a foundation for accountability, allowing you to identify potential issues early in the supply chain.

For example, if a defect is traced to a particular batch of materials, supplier mapping enables you to quickly identify the source and take corrective action.

Product Traceability

Product traceability involves tracking the journey of individual products and their components from the production process to the point of sale. This level of traceability is essential for providing detailed information about each product’s lifecycle, from raw material sourcing to final delivery.

With product traceability, you can monitor the performance of your production processes and identify areas for improvement. For instance, RFID technology and barcode systems can be used to record data at each stage of production. This ensures accurate data is available for inventory management, quality assurance, and addressing customer complaints.

Product traceability also plays a vital role in reducing risks associated with defective products. If a finished product is recalled, you can quickly identify the affected batches and trace them back to the production line or supplier responsible.

Material Traceability

Material traceability provides deeper visibility into the sourcing and production of raw materials used to create a product. This level is particularly important for industries such as automotive, pharmaceuticals, and food manufacturing, where the quality and integrity of materials directly impact the safety and performance of the finished goods.

By adopting material traceability solutions, you can maintain a complete record of each material’s origin, quality checks, and usage in the production process. This involves detailed documentation, such as batch numbers, test results, and records of inspections conducted during manufacturing. With this information, you can ensure compliance with international standards and regulatory requirements.

Material traceability also enables manufacturers to quickly identify and address issues related to contaminated products or defective materials. For example, if a problem is traced to a specific batch of raw material, you can determine its exact location in the production line and prevent further disruptions.

What are the Benefits of Traceability in Manufacturing?

Through robust traceability systems, manufacturers can monitor the entire supply chain and production processes with accurate data.

Below are the key advantages traceability brings to the manufacturing process.

Quality Assurance and Control

Traceability plays a critical role in ensuring consistent product quality. By tracking raw materials, production workflows, and finished goods, manufacturers can maintain high standards and identify quality issues early.

For instance, internal traceability allows you to monitor production lines and detect defective products before they move further in the supply chain. Traceability software generates detailed information, enabling you to make continuous improvements to meet industry regulations and maintain customer trust.

Risk Mitigation

Traceability systems help reduce risks such as product recalls and defective batches by identifying problems at their root cause. Whether it’s tracking contaminated products back to their raw material sources or pinpointing errors on the production line, traceability ensures issues are addressed quickly and effectively.

For example, backward traceability allows you to locate affected products and remove them from the supply chain, minimizing disruption and safeguarding your reputation. These systems are especially valuable in industries like automotive or pharmaceuticals, where safety and compliance are critical.

Robust Data Collection

Traceability systems generate comprehensive and accurate data at every stage of the manufacturing process. This data provides insights into production efficiency, inventory management, and quality assurance.

Using tools like RFID technology and barcoding, manufacturers can track products and raw materials in real time. These records are essential for conducting regular audits, ensuring regulatory compliance, and responding to customer complaints. With robust data collection, you gain complete traceability, which improves decision-making and supports long-term operational goals.

Production Efficiency

Streamlining workflows is another advantage of implementing traceability systems. By improving visibility across the supply chain, manufacturers can optimize production processes and reduce waste.

For instance, integrating traceability solutions into your manufacturing processes helps you quickly identify bottlenecks or inefficiencies on the shop floor. Real-time information allows you to adjust operations, maintain inventory control, and ensure production efficiency. Lean manufacturing principles can also be applied more effectively, ensuring resources are used responsibly and costs are minimized.

Regulatory Compliance

Meeting regulatory requirements is a primary driver for adopting traceability systems in manufacturing. These systems provide the detailed documentation needed to demonstrate compliance with industry regulations and international standards like ISO 9001 or industry-specific frameworks.

Traceability allows manufacturers to track raw materials, components, and finished products throughout the supply chain. This comprehensive record-keeping ensures that your production processes align with legal and quality control mandates.

Powerful Analytics

Traceability systems generate robust datasets that can be leveraged to improve production processes and supply chain management. Advanced analytics tools transform this data into actionable insights, helping manufacturers identify inefficiencies, reduce waste, and optimize workflows.

For example, analyzing traceability data can reveal bottlenecks in the production line or pinpoint trends in defective products. These insights enable continuous improvement by addressing root causes and enhancing production quality.

Revenue Opportunities

Enhanced traceability opens new avenues for revenue generation by increasing operational efficiency and building customer trust. Transparent tracking systems appeal to consumers who value ethical sourcing and quality assurance, particularly in industries like food, pharmaceuticals, and automotive manufacturing.

Moreover, traceability can reduce financial losses associated with recalls or defective products. By quickly identifying and isolating affected products, you minimize disruptions to your business and protect your bottom line. This proactive approach not only safeguards existing revenue streams but also strengthens your brand’s reputation, creating opportunities to attract new customers and expand into emerging markets.

Better Accuracy and Profitability

Traceability systems reduce errors by enabling precise tracking of materials, components, and finished goods throughout the production process. This level of accuracy minimizes waste, prevents mismanagement, and improves inventory control.

For instance, RFID tags and barcode scanning ensure that inventory levels are monitored in real time, reducing the likelihood of overproduction or stock shortages. Accurate tracking also supports lean manufacturing principles by maximizing resource use and lowering operational costs.

Consumer Trust and Brand Reputation

Transparency in manufacturing builds confidence among consumers. Traceability systems demonstrate your commitment to quality and accountability by providing detailed information about product origins, production processes, and quality checks.

This level of transparency reassures customers that your products meet high standards and comply with industry regulations. In the event of a product recall, a robust traceability system allows you to act swiftly, minimizing damage to your brand’s reputation. By consistently delivering reliable, high-quality products, you enhance customer loyalty and position your business as a trusted leader in your industry.

What are Key Components and Systems in Traceability?

Traceability systems are essential for maintaining visibility, compliance, and efficiency in the manufacturing process. They enable manufacturers to monitor the movement of raw materials, components, and finished products throughout the supply chain. Below, we discuss the key components of a traceability system and the technologies that facilitate its implementation.

What Are the Key Components of a Traceability System?

An effective traceability system is built on several critical components that work together to ensure accurate data collection, seamless tracking, and efficient management. These include:

- Unique Identifiers: Assigning unique IDs to raw materials, components, and finished products is essential for detailed tracking. These identifiers help manufacturers trace specific products or batches throughout the supply chain and production line.

- Record-Keeping Systems: A robust system for recording data at every stage of the manufacturing process ensures that manufacturers can access complete and accurate information when needed. This is crucial for regulatory compliance and quality assurance.

- Labeling and Tagging: Barcode labels and RFID tags are used to mark products and materials. These technologies simplify data capture and provide a reliable way to track items in real time.

- Data Storage and Management: Centralized databases or cloud-based systems store traceability data, ensuring it is accessible and secure. These systems support regular audits and compliance reporting.

- Integration with Manufacturing Execution Systems (MES): MES platforms enhance traceability by providing real-time data about production processes, inventory levels, and product quality.

What are Technologies That Facilitate Traceability?

Technological advancements have made traceability systems more efficient and accessible for manufacturers. Below, we discuss the most widely used technologies in traceability.

Barcode Scanning

Barcode scanning is a foundational technology for traceability systems. It uses machine-readable codes to label products and materials, providing a quick and accurate way to track items throughout the supply chain.

- How It Works: Barcodes contain encoded data about the product, such as batch numbers, manufacturing dates, or locations. Scanners read this information and feed it into traceability software for real-time monitoring.

- Benefits: Barcode scanning enhances production efficiency by automating data collection, reducing human error, and improving inventory management. It is widely used in industries like automotive and pharmaceuticals due to its reliability and cost-effectiveness.

RFID (Radio Frequency Identification)

RFID technology takes traceability to the next level by enabling wireless tracking of products and materials. Unlike barcodes, RFID tags can be scanned from a distance, even without a direct line of sight.

- How It Works: RFID systems use tags embedded with microchips to store product data. These tags communicate with RFID readers, transmitting information about the item’s location and status.

- Benefits: RFID technology is particularly valuable for tracking high volumes of inventory across large supply chains. It offers real-time visibility, faster scanning speeds, and better data accuracy compared to traditional methods.

QR Codes

QR codes are widely used in manufacturing industries for efficient tracking and data collection. These two-dimensional barcodes can store detailed information about a product, including its batch number, origin, and production date.

- How They Work: QR codes are scanned using smartphones or specialized devices. This instantly retrieves product details and integrates them into the traceability system.

- Benefits: They enable real-time visibility, reduce human error, and simplify the monitoring of individual products in the supply chain.

ERP (Enterprise Resource Planning) Systems

ERP systems are central to managing traceability in manufacturing. They integrate various business processes, including inventory control, production planning, and compliance tracking.

- How They Work: ERP platforms consolidate data from multiple sources, such as supplier records and shop floor activities, into a unified system.

- Benefits: By providing a complete record of materials and processes, ERP systems help you ensure compliance with regulatory requirements and improve overall production quality.

MES (Manufacturing Execution Systems)

MES platforms focus on the production process, offering real-time monitoring of shop floor operations. They bridge the gap between enterprise-level planning and factory-level execution.

- How They Work: MES tracks production workflows, from raw material input to finished product output, capturing data at each stage.

- Benefits: This technology ensures that manufacturers can quickly identify quality issues, minimize waste, and achieve complete traceability in their operations.

Blockchain Technology

Blockchain technology is emerging as a robust solution for ensuring transparency and trust in traceability systems. It provides a decentralized and tamper-proof record of transactions.

- How It Works: Blockchain creates an immutable ledger where every step in the supply chain is recorded and verified by multiple parties.

- Benefits: This enhances consumer trust, reduces the risk of fraud, and simplifies product recall processes by providing a clear audit trail.

IIoT (Industrial Internet of Things) Devices

IIoT devices connect machines, sensors, and systems to enhance traceability. They enable real-time data collection and analysis, creating a smart and responsive manufacturing environment.

- How They Work: Sensors embedded in production lines collect data on equipment performance, material movement, and environmental conditions. This data is transmitted to a central traceability system for analysis.

- Benefits: IIoT devices improve production efficiency, support predictive maintenance, and ensure that all records related to manufacturing are accurate and up-to-date.

Cloud Computing

Cloud computing plays a crucial role in modern traceability systems by enabling real-time visibility across the entire supply chain. It allows manufacturers to store, access, and analyze data securely from any location.

- How It Works: Cloud platforms collect and centralize data from production lines, inventory systems, and supplier networks.

- Benefits: They enhance transparency, support scalability, and improve data accuracy, ensuring compliance with industry regulations and streamlining operations.

Data Analytics Software

Data analytics software enables manufacturers to derive actionable insights from traceability information. By analyzing production processes and supply chain activities, it helps identify inefficiencies and potential risks.

- How It Works: The software processes detailed information collected at every stage of the production process to highlight trends and root causes of quality issues.

- Benefits: It supports continuous improvement, optimizes production efficiency, and reduces the likelihood of defective products reaching consumers.

AI (Artificial Intelligence) and Machine Learning

AI and machine learning elevate traceability by automating complex tasks and predicting potential issues. These technologies process vast amounts of data to detect anomalies and optimize production quality.

- How They Work: AI-powered systems analyze real-time data from sensors, machines, and records to identify inefficiencies and predict failures.

- Benefits: They reduce human error, improve compliance, and enhance production efficiency by automating routine tasks and offering predictive insights.

Unique Identifiers in Traceability

Unique identifiers are the foundation of any traceability system. They assign a distinct identity to every product, sub-assembly, or raw material, enabling detailed record-keeping and efficient tracking.

- Why They Matter: Unique IDs ensure that every component in the supply chain is traceable. Whether it’s a batch of raw materials or a finished product, these identifiers make it possible to track items at every stage.

- Applications: QR codes, barcodes, and RFID tags are common methods for applying unique identifiers. These tools simplify inventory control, facilitate quality checks, and enable manufacturers to quickly identify defective products.

How to Implement Effective Traceability in Manufacturing

To implement a system effectively, you need to address key steps such as data acquisition, process integration, and employee training. These components work together to create complete traceability for raw materials, production processes, and finished products.

- Assess Current Processes: Begin by evaluating your existing production processes and supply chain. Identify critical components and areas prone to inefficiencies or compliance risks. This includes tracking raw materials, monitoring production lines, and documenting quality control records.

- Choose Appropriate Tools: Select traceability solutions like RFID technology, barcode systems, or traceability software tailored to your business needs. These tools ensure accurate data collection and improve compliance with industry regulations.

- Integrate Systems Across Operations: Implement a traceability system that connects various departments, from procurement to distribution. This ensures real-time visibility and complete records across the entire business.

- Establish Regular Audits: Schedule frequent audits to verify the accuracy of collected data and address any gaps. This helps quickly identify defective products and ensures compliance with regulatory standards.

Use of Automated Data Acquisition

Automating data collection through Industrial Internet of Things (IIoT) devices is vital for modern manufacturing industries. These devices collect real-time data from production lines, inventory systems, and equipment.

- Why It Matters: Automated systems minimize human error, improve production efficiency, and provide accurate data. By integrating IIoT sensors, you can monitor key components of your production process and quickly identify issues like defective products or contaminated materials.

- How It Works: Data is captured at each stage of the production line and stored in a centralized traceability system, ensuring quick access and comprehensive records.

Employee Training

Employee training is a crucial step in maintaining the integrity of a traceability system. Your team must understand how to use traceability software and follow established protocols for recording and managing traceability information.

- Training Goals: Teach employees how to operate automated systems, interpret collected data, and follow compliance procedures. This reduces the risk of human error and ensures adherence to industry regulations.

- Implementation: Provide hands-on workshops, detailed guides, and ongoing support to familiarize staff with the new system.

Supplier Traceability Controls

Supplier traceability controls involve establishing processes to ensure your suppliers meet regulatory requirements and provide accurate data about their raw materials. Verifying supplier accountability is a critical step in any traceability system, as it ensures the integrity of the materials entering your production line.

- How It Helps: By implementing robust controls, you can quickly identify affected products in case of quality issues or recalls. This minimizes risks and builds consumer trust.

- Steps to Enforce: Conduct regular audits of supplier records, implement traceability software for real-time monitoring, and require compliance documentation for raw materials.

Lean Manufacturing Processes

Incorporating lean manufacturing principles simplifies traceability by reducing inefficiencies and streamlining workflows. Lean processes prioritize the efficient use of resources, helping manufacturers maintain detailed records and optimize production quality.

- Implementation Tips: Focus on accurate data collection using tools like RFID tags and barcodes. Maintain continuous improvement by analyzing production inefficiencies and adjusting workflows.

What is a Traceability Audit?

A traceability audit is a systematic process used in manufacturing industries to evaluate and verify the ability of a traceability system to track products, raw materials, and components throughout the supply chain. Its primary goal is to ensure compliance with regulatory requirements, improve production efficiency, and maintain quality control. By auditing records related to product traceability, manufacturers can identify gaps, improve processes, and meet industry regulations.

Through regular audits, companies can ensure the accuracy of their data, minimize human error, and maintain a complete record of production processes. These audits also play a crucial role in managing risks such as product recalls and customer complaints.

How Do Traceability Audits Ensure Compliance with Regulations?

Traceability audits ensure compliance by verifying that manufacturing processes adhere to relevant regulations and standards. They assess the effectiveness of systems in tracking raw materials and finished products across the supply chain, reducing the risks of non-compliance. By maintaining detailed information on every stage of the production line, audits can identify and rectify potential issues.

Traceability is especially important in industries like pharmaceuticals, food, and automotive, where safety and quality are critical. Audits confirm that companies comply with regulatory standards and industry-specific requirements, ensuring the traceability of affected products in case of recalls or quality concerns.

Compliance with International Standards

Traceability audits are critical for aligning manufacturing operations with international standards such as ISO 9001 (quality management) and ISO 8402 (quality vocabulary). These standards require manufacturers to maintain consistent records related to the production process and ensure traceability for quality assurance.

By conducting regular audits, companies can verify compliance with standards and gain a competitive edge in global markets. Standards such as HACCP for food safety or IATF 16949 for automotive quality require detailed tracking of raw materials, production processes, and finished goods.

Legal and Ethical Considerations in Traceability Audits

Traceability audits are not only a matter of regulatory compliance but also involve significant legal and ethical considerations. Maintaining traceability information helps companies demonstrate accountability in case of defective products or customer complaints. Legally, manufacturers must comply with industry-specific laws that mandate traceability for public safety and environmental responsibility

How Do Traceability Audits Enhance Product Quality and Safety?

By verifying the ability of a traceability system to track raw materials and finished products, these audits help manufacturers identify and address issues that could compromise quality. They provide detailed information about the production process, allowing for consistent quality assurance and minimizing the risk of defective products reaching the market.

With traceability audits, manufacturers can quickly identify and isolate affected products in the event of product recalls, reducing the impact on consumers and maintaining trust. Regular audits ensure compliance with regulatory requirements, such as those governing food safety, automotive manufacturing, and pharmaceuticals, to safeguard end-user safety.

What Should You Expect During a Traceability Audit?

A traceability audit involves a structured assessment of the traceability systems used within manufacturing operations. Auditors review the processes and records related to product traceability, ensuring that the system provides accurate data and aligns with regulatory compliance requirements. The process typically starts with evaluating the traceability software, systems, and data collection methods to verify complete records for raw materials, production steps, and finished goods.

Auditors also assess inventory management practices, ensuring that all batch numbers and critical components can be traced back to their origins. The audit examines the organization’s ability to track defective products and respond effectively to customer complaints or product recalls.

Pre-Audit Preparation

Preparing for a traceability audit is essential to ensure a smooth process and accurate results. Here are key steps to organize and verify before the audit begins:

- Review Documentation: Ensure all records related to the production process, such as batch numbers, raw material origins, and finished product details, are complete and up to date.

- Check Traceability Systems: Confirm that the traceability software is functioning correctly and integrates with inventory management systems.

- Verify Regulatory Compliance: Cross-check that all processes align with industry regulations and international standards, such as ISO certifications.

- Organize Quality Control Records: Prepare detailed records of quality checks conducted throughout the production line to demonstrate adherence to quality assurance practices.

- Conduct Internal Audits: Perform internal reviews to identify and address potential gaps in the traceability system before the external audit.

- Train Employees: Ensure staff understands the traceability processes and can provide necessary information during the audit.

During the Audit

During a traceability audit, several critical activities and checks are conducted to assess the reliability of the traceability system. These include:

- Reviewing Documentation: Auditors evaluate records related to raw materials, production lines, and finished goods to ensure complete traceability.

- Testing System Functionality: Traceability software is tested for accuracy and its ability to track products across the supply chain.

- Assessing Inventory Management: Procedures for managing batch numbers, inventory control, and defective products are closely examined.

- Examining Quality Control Measures: Records from quality assurance processes are checked to verify compliance with regulatory standards and production quality requirements.

- Simulating Scenarios: Auditors may perform product recall simulations to test the system’s efficiency in quickly identifying affected products.

Post-Audit Activities

Once the audit is complete, several follow-up procedures are implemented to address findings and improve the traceability system. These actions typically include:

- Audit Reporting:A detailed report outlines the audit’s findings, highlighting strengths and identifying areas requiring improvement.

- Corrective Action Plans: Specific recommendations are provided to address deficiencies, such as improving data accuracy or updating traceability software.

- Employee Feedback Sessions: Key team members are briefed on the audit results, and training sessions may be scheduled to address identified gaps in knowledge.

- System Updates: Necessary updates to the traceability system are implemented to ensure compliance and enhance functionality.

- Ongoing Monitoring: Processes are established for continuous improvement, including regular audits and system testing to maintain complete traceability.

What are the Best Practices and Optimization of Traceability in Manufacturing?

Implementing effective traceability in manufacturing involves adopting practices that streamline processes, ensure compliance, and enhance production quality. Here are some best practices you can follow:

- Standardize Data Collection: Use traceability software to capture consistent and accurate data across production processes. This ensures reliable records related to raw materials and finished products.

- Leverage Real-Time Monitoring: Employ technologies like RFID tags and sensors for real-time visibility of inventory and the production line.

- Conduct Regular Audits: Perform routine evaluations to identify gaps in the traceability system and improve compliance with regulatory requirements.

- Integrate Systems Across the Supply Chain: Synchronize traceability systems with supplier data for complete traceability from raw material sourcing to distribution.

Integrating Traceability with Existing Systems

Incorporating new traceability measures into your manufacturing process can be seamless when approached strategically. Start by ensuring compatibility between traceability software and existing systems, such as enterprise resource planning (ERP) and inventory management tools. This enables the smooth transfer of accurate data between platforms, minimizing human error.

Communication with suppliers is equally important. Align their tracking systems with your own to enable end-to-end visibility across the supply chain. You may also need to update your shop floor equipment, like barcode scanners or RFID readers, to support real-time tracking. Ensure that the integration includes production line monitoring to capture detailed information on batch numbers and components.

Regular Monitoring and Auditing

Maintaining a robust traceability system requires consistent monitoring and regular audits. Continuous tracking of production processes ensures real-time visibility, enabling manufacturers to identify and address potential issues before they escalate. Tools like RFID technology and traceability software can automate this process, reducing the scope for human error.

Mock recalls are a valuable part of the auditing process. Simulating a product recall tests your system’s ability to quickly identify affected products, trace root causes, and minimize disruption. Additionally, audits ensure compliance with industry regulations by reviewing records and assessing the system’s alignment with regulatory requirements.

What are the Main Challenges in Implementing Traceability?

Implementing traceability in manufacturing is not without its challenges. One of the primary obstacles is the cost of upgrading systems. Traceability solutions, including software, sensors, and integration tools, can represent a significant investment, especially for small manufacturers. However, these costs are often offset by long-term benefits like improved production efficiency and reduced product recalls.

Another challenge lies in managing supplier relationships. Inconsistent data sharing or non-compliance from suppliers can create gaps in your traceability system. Clear communication and contracts specifying regulatory compliance and data-sharing standards are essential to overcoming this issue.

Cost Implications

One of the primary challenges in implementing traceability systems is the cost. Initial expenses include purchasing traceability software, upgrading equipment with RFID tags or barcode scanners, and integrating new systems into existing infrastructure. These investments are critical for ensuring accurate data capture and end-to-end product traceability. However, manufacturers must also consider ongoing costs, such as system maintenance, employee training, and regular audits.

To assess the financial impact, conduct a return on investment (ROI) analysis. While upfront costs may seem high, benefits like improved production efficiency, better inventory management, and reduced product recalls often outweigh the expenses.

Data Security Concerns

Data security is a significant concern for traceability systems, especially in industries requiring compliance with strict regulatory requirements. With large amounts of sensitive data, including records of raw materials, production processes, and supply chain transactions, ensuring data integrity is essential.

Manufacturers should implement robust cybersecurity measures, such as encryption, secure servers, and regular system updates, to protect traceability information. Internal access controls also play a role in reducing risks of unauthorized access or human error.

How to Analyze Data from Traceability Audits

Proper analysis ensures accurate insights into the production process, supply chain activities, and product traceability. By examining data, you can identify inefficiencies, quality issues, and risks related to compliance with industry regulations. Tools like traceability software and data analytics platforms enable the visualization of trends and patterns, making it easier to address gaps and optimize production efficiency.

Using Big Data Analytics in Traceability

Big data analytics transforms traceability in manufacturing by processing large datasets for actionable insights. These tools integrate with traceability systems to monitor the movement of raw materials and finished goods, enabling end-to-end visibility. By employing machine learning algorithms, manufacturers can quickly identify trends, predict potential issues, and assess the root cause of defects.

For example, real-time data collected via RFID tags and production sensors can highlight inefficiencies on the shop floor or supply chain. This enables manufacturers to improve production quality, ensure compliance, and reduce costly product recalls.

Proactive Monitoring

Proactive monitoring leverages advanced systems to anticipate potential problems before they escalate. Tools such as IoT-enabled sensors and traceability software allow real-time tracking of raw materials and components throughout the production process. This continuous oversight minimizes human error and ensures regulatory compliance.

How Does Industry 4.0 Influence Traceability?

Industry 4.0 reshapes manufacturing by integrating smart technologies into traditional processes, enhancing traceability systems. Advanced tools like IoT devices, blockchain, and AI-driven analytics create real-time visibility across supply chains and production lines. This allows manufacturers to track every stage of a product’s lifecycle, from raw materials to the finished product, ensuring complete traceability.

Updating and Upgrading Traceability Systems

Keeping your traceability system updated ensures it aligns with technological advancements and evolving industry regulations. Regularly reviewing traceability software and systems is essential to maintain accurate data and improve traceability across the production line. Upgrading tools like RFID technology, cloud-based storage, and real-time monitoring capabilities allows manufacturers to optimize production processes and respond to supply chain complexities.

Manufacturers should integrate updates with their internal traceability framework to minimize disruptions. Ensuring compatibility with existing systems is critical, as it allows seamless implementation without compromising production quality. Periodic training for your team on new technologies and practices ensures effective adoption and maximizes system benefits.

What Documentation is Essential for a Traceability Audit?

Effective traceability audits rely on comprehensive and well-maintained documentation. Critical records include data on raw materials, production processes, and batch numbers for finished products. This information helps identify affected products in case of customer complaints or product recalls. Detailed records related to inventory management, production line activities, and supply chain movements are equally important.

Documentation should also include compliance reports for industry regulations and international standards such as ISO 9001. Traceability software can simplify record-keeping by maintaining a complete record of activities in real time.

What Should Be Included in the Traceability Audit Checklist?

An effective audit checklist should cover the following:

- Raw Material Tracking: Ensure documentation of raw material origins and supplier details.

- Production Line Records: Verify data from the production process, including batch numbers and timestamps.

- Inventory Control: Review systems for inventory management and stock movements.

- Quality Assurance Data: Check for quality control measures and inspection records.

- Regulatory Compliance Reports: Confirm adherence to regulatory requirements and international standards.

- Supply Chain Transparency: Evaluate documentation for all supply chain stages to ensure complete traceability.

Conclusion

Traceability audits are essential for maintaining transparency, ensuring quality, and building trust in manufacturing. They go beyond compliance, helping you mitigate risks, enhance production processes, and deliver reliable products. By tracking raw materials and finished goods with advanced traceability systems, you can maintain clarity and control over operations.

As manufacturing embraces Industry 4.0, tools like RFID technology and big data analytics are transforming how we identify gaps and improve efficiency. These innovations, combined with proactive monitoring and adherence to evolving regulations, empower you to refine processes and stay competitive. Traceability audits are not just about meeting requirements—they’re an investment in excellence, paving the way for a stronger, more efficient future.

Frequently Asked Questions

What is the Role of Traceability Audit in the Supply Chain?

Traceability audits ensure every component in the supply chain is accounted for, from raw materials to the finished product. By monitoring the production process and documenting records related to the entire business, audits help maintain product traceability and identify risks before they impact production quality. These audits also verify compliance with industry regulations and provide a reliable way to address customer complaints or product recalls..

What Are the Regulatory Requirements for Product Traceability in Our Industry?

Regulatory requirements for product traceability vary by industry but often include adherence to international standards like ISO 9001 or specific guidelines for the automotive or pharmaceutical sectors. These standards mandate detailed record-keeping of production processes, inventory control, and batch numbers for finished goods. Maintaining compliance involves using traceability systems that capture data at every stage of the supply chain, ensuring accountability and facilitating quick identification of any affected products.