From my 10 years of experience working with Chinese suppliers, I must say that I am less concerned than other “industry experts” about the notoriety of the “Made in China” label.

Of course, there are scams and there are bad suppliers, who for example would say “yes” to everything and finally are not able to deliver, or who use “misunderstandings” as reasons to justify quality issues. But there also are good suppliers who deliver good quality of products, and even excellent quality when the customers engage properly with them and are clear on their needs.

Reducing the risks of quality issues involves acting on every part of the supply chain. When it comes to controlling non- conformities, setting a clear and complete set of specifications is one of, if not the most important part.

If you have stated your need in written or verbal communication with your supplier, it is the very first step of setting the specifications. But your need should be exhaustive and complete to minimize any risk of product non-conformity or dissatisfaction from your end user.

Here is important information you might want to integrate into your specifications sheet:

Order Information

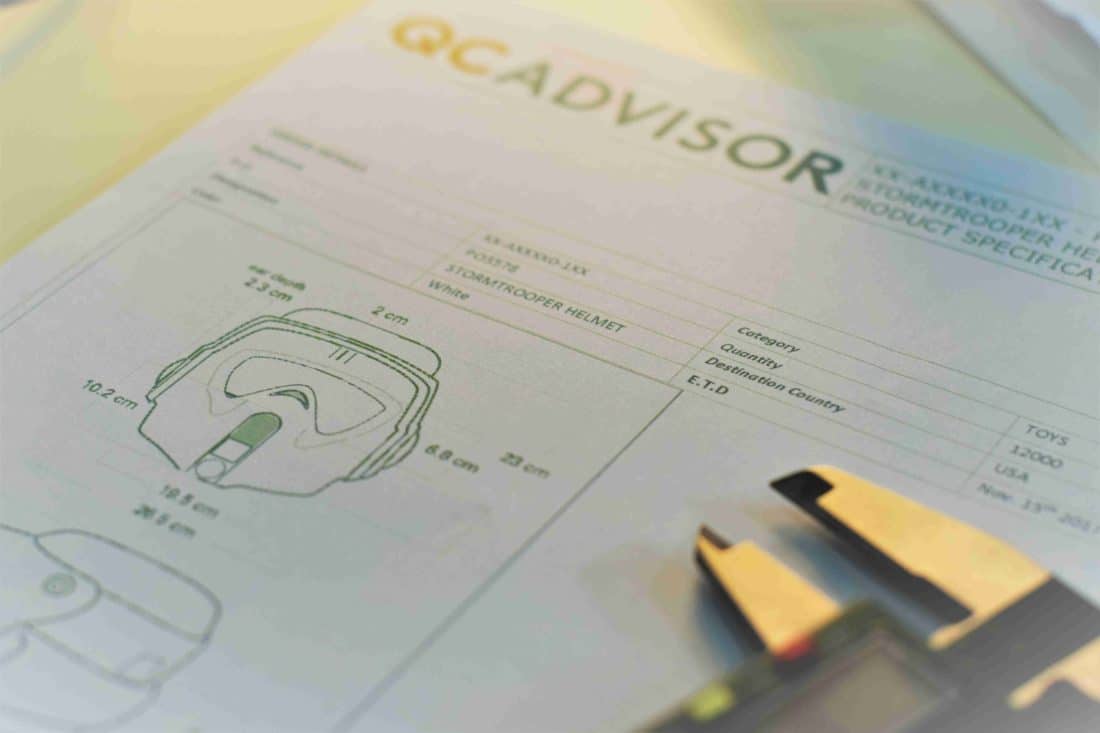

To avoid mistakes or mixed information about some crucial information such as order quantity or PO number, it is important to always state clearly, even if it seems obvious, information such as PO number, Order quantity, Product Designation, Color, Destination Country and E.T.D

Here is an example:

Product General Information

Going step by step into more detail, start with the product general information.

List the main aspects of the product such as size, material to be used, pantone code, logo, accessories and main functions of the product. Adding a clear photo of the product is also helpful.

Dimension and Weight

Dimensions and weight are also important. Include them in a clear manner, and add illustration if possible.

Marking, Packaging, and Packing

For your supply chain and fulfillment center, wrong marking, master cartons dimensions or carton quality can have a huge impact on your time-to-market and on your budget. You also need to be as detailed as possible in your requirements on marking, barcodes master carton and inner packing (if applicable). This will help you avoid misunderstandings and face beginners’ mistakes. If you have specific requirements such as Amazon FBA requirements for packing and packaging, you need to state them one by one. Avoid instructions such as “must comply with FBA Amazon requirements” without additional details. The rule of thumb is “state the obvious”.

Regulatory Standards

Failing to comply with the mandatory or safety regulations of your destination country might be very painful for your business. Everyday we see containers blocked because toys are not complying with EN 71 standards in Europe. Everyday Amazon seller accounts are closed due to local regulation and standards not being followed or even failure to provide the right certifications’ documentation.

Clearly describe what you are expecting from your supplier:

If they should provide the certificates, for which standards with which requirements (original or copy, within which period).

If you are the one responsible to test the product, make sure to clearly state what kind of sample you need and when, or to which laboratory factory they should send it to and under which conditions.

Expected Quality and QC process

Additionally, it’s advised, if you are working with a factory in China, to be very clear before production starts, about your expectations on the quality, by clarifying the Inspection criteria as well as the Acceptance Quality Limits and other Inspection process details.

Every project and product has its own specificity, content, and layout. The golden rule is that your products specifications must be consistent with the product you want your end users to have in their hands. It is important to reflect that in the most objective and exhaustive way possible, point by point. Details are very important here and they key is to be as detailed and granular as you can.