Good quality control practices are crucial for ensuring the reliability and safety of your products.

Among the most frequently used methods, AQL (Acceptable Quality Limit) tables have emerged as a powerful tool for random inspections.

The goal of this short presentation is to offer a comprehensive overview of how AQL works, its origins, and its significance in quality control processes, while also presenting additional information beyond the usual knowledge we commonly associate with AQL.

Understanding AQL

AQL tables help manufacturers and inspectors determine the number of units to be sampled and tested from a given batch. The tables are based on statistical principles and provide guidelines for acceptance or rejection of the batch based on the observed defects in the sample. The AQL level sets the maximum defect rate that is considered acceptable, while the sample size determines the confidence level of the inspection.

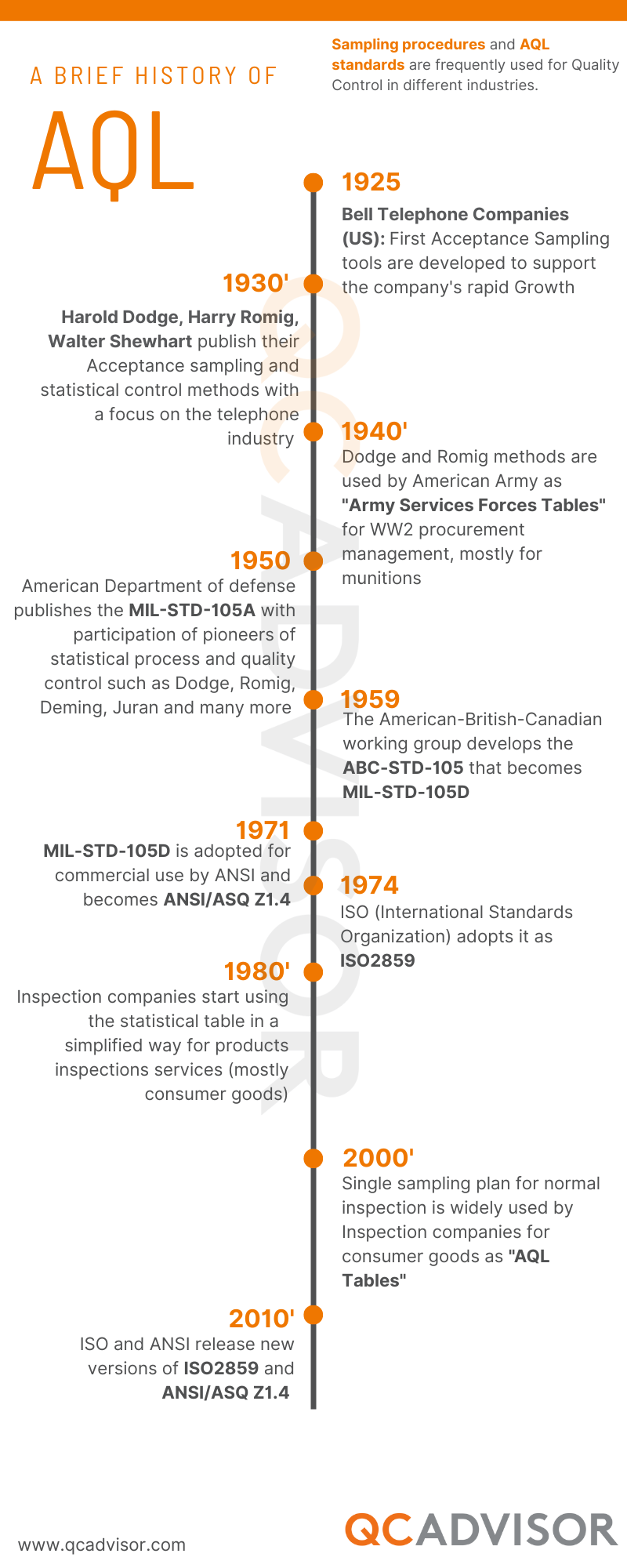

Origins of AQL

The concept of AQL originated from statistical quality control, a discipline that gained prominence in the mid-20th century. The development of AQL tables can be attributed to the works of prominent statisticians such as Dodge and Romig. Their pioneering efforts aimed to strike a balance between the cost of inspection and the risk of accepting defective products.

Their hard work will result in the release of the MIL-STD-105 standards, also known as the “Military Standard,” by the American Department of Defense. These standards will then be published as ANSI/ASQZ1.4 in the US and ISO2859 by the International Organization for Standardization (ISO).

The ISO2859 and ANSI/ASQZ1.4 standards outline various types of inspections, such as tightened, normal, and reduced, each catering to specific stringency requirements. The standards also include different sampling plans, simple, double, and multiple schemes. Furthermore, ISO2859 standard emphasizes that these inspection schemes are designed primarily for application in a continuous series of lots.

However, in recent times, the single sampling plan for normal inspection has gained widespread popularity and acceptance, specially for consumer goods inspections.

This approach simplifies the sampling process, streamlines decision-making, and offers a practical and efficient means of assessing product quality while ensuring compliance with standards and customer expectations.

Key takeaways

- AQL Levels: Determining the acceptable defect rate based on the criticality of the product and customer expectations.

- Sampling Plan: Selecting an appropriate sample size from the batch using statistical techniques.

- Inspection and Decision: Randomly inspecting the sample units and comparing the observed defects with the AQL table to make a decision on batch acceptance or rejection.

Benefits of AQL

- Cost-effective: AQL tables enable efficient quality control by reducing the need for 100% inspection.

- Statistical Confidence: The use of statistical methods ensures a representative sample and reliable decisions.

- Risk Mitigation: AQL tables help minimize the risk of accepting defective batches, ensuring customer satisfaction and brand reputation.

More for you

At QCADVISOR, we have improved the table’s readability by directly indicating the sample size instead of using traditional letter-based references. This enhancement not only makes the table easier to read but also reduces the likelihood of errors and mistakes.

Download the table here: PDF/PNG:

SAMPLE SIZE TABLE (ISO 2859-1)

SINGLE SAMPLING PLAN FOR NORMAL INSPECTION (ISO 2859-1)

AQL tables have revolutionized quality control by providing a systematic and statistically sound approach to random inspection. Their origins lie in the field of statistical quality control, and they continue to play a vital role in ensuring the production of reliable and safe products.

By striking a balance between inspection costs and risk, AQL tables enhance efficiency, reduce costs, and uphold the quality standards expected by customers and industries alike.

Any question or comment about your Quality Control?

Reach out to QCADVISOR today and let us be your trusted guides.