A factory audit provides insight into whether suppliers’ processes meet regulatory standards and helps ensure that they abide by good manufacturing practices. Many businesses choose to conduct factory audits before entering into contracts with new suppliers, as this step confirms the supplier’s reliability and legal compliance.

By performing factory audits, you not only uphold product quality but also safeguard your company’s reputation and financial health. It’s no surprise, then, that the global Factory Audit Service Market is on the rise—valued at approximately USD 0.4 billion in 2023 and projected to reach USD 1 billion by 2032, with a CAGR of about 10% from 2023 to 2032.

There are several types of factory audits—like compliance audits, process audits, and quality audits—each targeting specific areas of concern. In this article, we will explore these various audits, how they benefit your business, what happens during a factory audit, including the main steps and typical checklists involved. You will also learn why using the services of a third-party factory auditor might be the best choice to evaluate your supplier facility and its capabilities.

What Is a Factory Audit?

A factory audit is a through evaluation that is used to ensure that manufacturing facilities meet specific customer standards and regulations, as well as the requirements for various regions and markets.

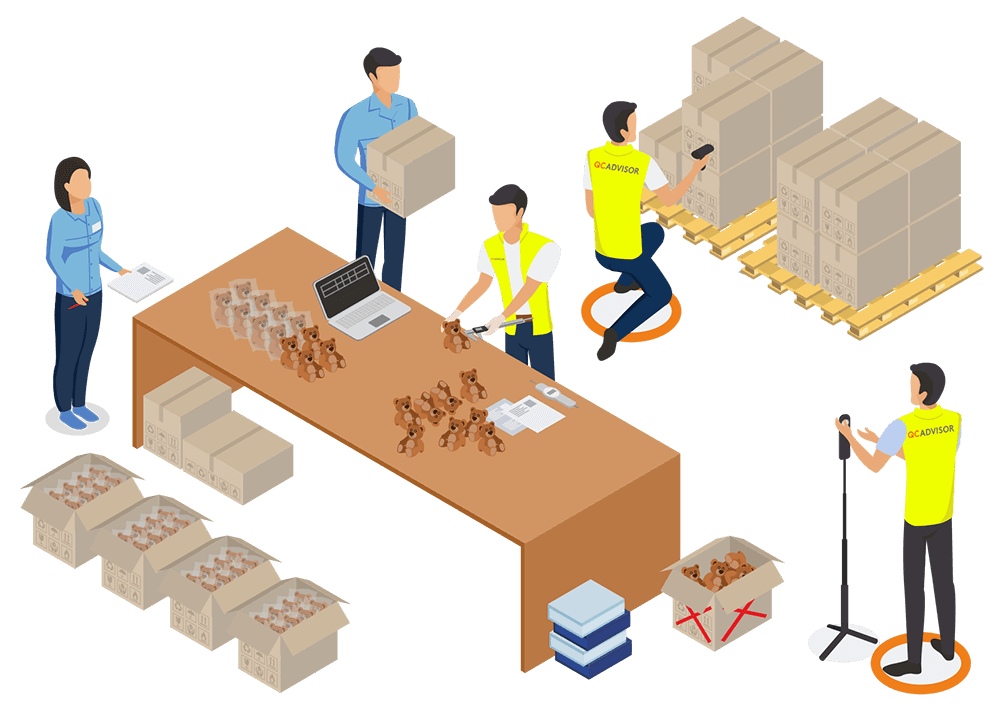

A typical factory auditing process involves a thorough assessment of a facility’s capabilities, including its machinery, production systems, quality control processes, and workplace environment.

Factory audits help identify areas for improvement and ensure that the facility operates efficiently and in compliance with applicable standards and regulations.

Why Are Factory Audits Essential for Businesses?

Factory audits are critical for maintaining quality, compliance, and efficiency within the supply chain. By regularly conducting these audits, businesses can ensure that their manufacturing processes align with industry standards, such as ISO 9001. This alignment not only guarantees product quality but also enhances customer satisfaction and trust.

Here are the five most notable benefits of conducting factory audits:

- Quality Assurance: Aligning with internationally recognized standards, such as ISO 9001, ensures that suppliers adhere to best practices in quality management. Factory audits help identify gaps in process control, product design, and customer satisfaction, enabling you to make informed decisions and drive continuous improvement in product quality. This proactive approach minimizes risks, such as production delays, product defects, and potential legal issues.

- Supply Chain Transparency: Factory audits provide valuable insights into supplier performance, revealing potential weaknesses in production, labor practices, and environmental management. This transparency allows you to make better sourcing decisions and mitigate potential risks, contributing to more sustainable and ethical supply chains.

- Compliance with Regulations: Factory audits help ensure your organization complies with national and international regulations, including labor laws, environmental standards, and industry-specific requirements. Addressing product compliance issues can prevent significant fines, legal consequences, and reputational damage.

- Cost Optimization: By identifying inefficiencies and areas for improvement, factory audits can lead to cost optimization. Implementing corrective actions can reduce waste, increase productivity, and improve resource allocation, resulting in long-term cost savings for your business.

- Strengthening Business Relationships: Factory audits facilitate open communication and mutual understanding between you and your suppliers. Demonstrating a commitment to quality and ethical practices fosters trust and promotes long-lasting business relationships, benefiting both parties.

What Are the Different Types of Factory Audits?

There are several types of factory audits like compliance audits and quality audits, each focusing on specific areas of concern. Understanding the different types of factory audits allows businesses to select the appropriate audit based on their specific needs and goals.

Ethical Audits

Ethical audits focus on the social responsibility and ethical practices within a manufacturing facility. These audits assess the working conditions, labor practices, and overall treatment of workers. The goal is to ensure that the facility adheres to ethical standards, such as fair wages, safe working conditions, and the prohibition of child or forced labor.

Ethical audits are particularly important for companies looking to maintain a positive brand image and avoid potential reputational damage due to unethical practices within their supply chain.

Quality Audits

Quality audits are designed to evaluate the quality management systems in place within a manufacturing facility. These audits assess whether the facility is capable of producing products that meet the required quality standards, such as ISO 9001.

During a quality audit, auditors will examine the production processes, quality control measures, and the consistency of product output. The primary objective of quality audits is to ensure that the products manufactured meet customer expectations and comply with industry standards, thereby reducing the risk of product defects and recalls.

Environmental Audits

Environmental audits are designed to assess a manufacturing facility’s adherence to environmental regulations and standards. These audits focus on the facility’s impact on the environment, evaluating factors such as waste management, energy consumption, and pollution control.

The goal of an environmental audit is to ensure that the facility minimizes its environmental footprint, complies with local and international environmental laws, and implements sustainable practices. By conducting environmental audits, companies can not only meet regulatory requirements but also enhance their brand reputation by demonstrating a commitment to environmental stewardship.

Social Compliance Audits

Social compliance audits evaluate a manufacturing facility’s adherence to ethical standards regarding labor practices and working conditions. These audits focus on ensuring that the facility complies with labor laws, human rights standards, and company-specific ethical guidelines. Key areas assessed in social compliance audits include worker safety, fair wages, working hours, and the prohibition of child and forced labor.

Social compliance audits are essential for companies that prioritize ethical sourcing and seek to maintain a positive image in the eyes of consumers and stakeholders. Conducting these audits helps businesses ensure that their supply chains are free from exploitative practices, thereby protecting their brand and fostering long-term relationships with ethically-minded customers.

Safety Audits

Safety audits are essential for assessing a manufacturing facility’s adherence to safety standards and regulations. These audits focus on evaluating the workplace environment, identifying potential hazards, and ensuring that safety protocols are in place to protect employees and visitors. Key areas assessed in safety audits include the proper use of personal protective equipment (PPE), fire prevention measures, emergency preparedness, and compliance with occupational safety regulations.

By conducting regular safety audits, companies can reduce the risk of workplace accidents, improve employee well-being, and ensure compliance with safety laws, ultimately contributing to a safer and more productive working environment.

Process Audits

Process audits examine the efficiency and effectiveness of a facility’s production processes. These audits focus on the methods and procedures used in manufacturing to ensure they meet the required standards for quality, consistency, and efficiency. During a process audit, auditors assess various aspects of the production line, including machinery setup, process controls, and the integration of quality management systems like ISO 9001.

The goal of a process audit is to identify areas for improvement, streamline production, and reduce waste, leading to enhanced product quality and operational efficiency. Companies that regularly conduct process audits can maintain high standards of production and remain competitive in the marketplace.

Product Audits

Product audits are focused on evaluating the quality of the products manufactured within a facility. These audits assess whether the finished products meet the specified requirements, including industry standards, customer specifications, and regulatory compliance.

During a product audit, auditors examine various aspects of the product, such as its design, materials, functionality, and overall compliance with the predetermined standards. The primary goal is to ensure that the products are consistent, free from defects, and meet customer expectations. Product audits are crucial for maintaining product quality and avoiding costly recalls or reputational damage due to substandard products.

System Audits

System audits are designed to evaluate the effectiveness of a facility’s management systems, such as quality management systems (QMS), environmental management systems, and safety management systems. These audits ensure that the systems in place are functioning as intended and are capable of meeting the facility’s operational requirements and compliance standards.

System audits often involve a thorough review of documentation, processes, and procedures to verify that the management systems align with standards such as ISO 9001. The goal of a system audit is to identify any gaps or areas for improvement in the management systems, ensuring that they contribute to continuous improvement, compliance, and operational efficiency.

Compliance Audits

Compliance audits are conducted to ensure that a manufacturing facility adheres to relevant laws, regulations, and industry standards. These audits cover various aspects of a facility’s operations, including labor practices, environmental regulations, and safety standards. During a compliance audit, auditors review documentation, inspect the facility, and assess whether the operations align with legal and regulatory requirements.

The goal is to identify any non-compliance issues that could result in legal penalties, reputational damage, or operational disruptions. Compliance audits are critical for maintaining a company’s reputation, avoiding fines, and ensuring that all operations meet the required standards. Regular compliance audits also help businesses stay ahead of regulatory changes, ensuring continuous improvement and adherence to best practices.

Security Audits

Security audits focus on evaluating the security measures in place at a manufacturing facility. These audits are designed to assess how well the facility protects its assets, including physical goods, intellectual property, and confidential information. A security audit examines the facility’s security protocols, such as access control, surveillance systems, and data protection measures.

The purpose of a security audit is to identify vulnerabilities that could lead to theft, data breaches, or other security incidents. By conducting regular security audits, businesses can mitigate risks, protect their assets, and ensure that their operations are secure. Security audits are particularly important for companies that handle sensitive information or operate in industries where security is a top priority, such as defense, technology, and pharmaceuticals.

Custom-Trade Partnership Against Terrorism (CTPAT) Audits

The Custom-Trade Partnership Against Terrorism (CTPAT) audit is a security initiative led by U.S. Customs and Border Protection. This audit is designed to strengthen international supply chains and improve U.S. border security by working closely with the private sector.

Companies that participate in CTPAT agree to implement certain security measures throughout their supply chains, which are then verified through a CTPAT audit. A CTPAT audit focuses on assessing the security practices within a company’s supply chain, including the physical security of the manufacturing facilities, personnel security, procedural security, and the security of IT systems.

The audit ensures that the company is compliant with CTPAT guidelines, which are critical for minimizing risks related to terrorism and ensuring the safe and secure movement of goods into the United States. Companies that successfully pass a CTPAT audit can benefit from a reduced number of inspections at the border and expedited processing of shipments, making it an advantageous certification for businesses engaged in international trade.

How Should a Business Decide Which Type of Audit to Conduct?

Choosing the right type of factory audit depends on several factors, including the nature of the business, the regulatory requirements of the industry, and the specific goals of the audit.

Here’s a guide with six points on how to make this decision:

- Assess Your Business Needs: Start by identifying the primary concerns and objectives of your business. Are you focusing on product quality, regulatory compliance, security, or environmental impact? Understanding your priorities will help you determine which audit type aligns best with your goals.

- Consider Industry Standards: Depending on your industry, certain audits may be more critical. For example, if you are in a high-risk industry such as pharmaceuticals or defense, security audits like CTPAT might be essential. On the other hand, if your focus is on maintaining product quality, a product or process audit would be more appropriate.

- Regulatory Requirements: Ensure that your chosen audit meets any regulatory requirements specific to your industry. For example, ISO 9001 compliance might necessitate regular quality management system audits to ensure ongoing adherence to industry standards.

- Supply Chain Transparency: If your business is concerned with the integrity and security of your supply chain, security audits like CTPAT or compliance audits that focus on labor practices and working conditions might be necessary.

- Risk Management: Consider conducting audits that address the most significant risks to your business. For example, if your company handles sensitive information, a security audit might be crucial to mitigate potential cyber threats.

- Long-term Goals: Align your audit strategy with the long-term goals of your business. If continuous improvement and sustainability are priorities, environmental audits or continuous improvement audits may be beneficial.

When Should You Schedule a Factory Audit?

Determining the right time to schedule a factory audit is crucial for ensuring that your manufacturing processes meet quality standards, regulatory requirements, and customer expectations. The timing of an audit can significantly impact its effectiveness in identifying potential issues and improving overall operations.

Here are four tips to help you determine the optimal timing for different types of factory audits:

- As a Final Step When Qualifying New Suppliers: One of the most critical times to conduct a factory audit is when you are in the process of qualifying new suppliers. After initial assessments, such as reviewing documentation and evaluating product samples, conducting an on-site audit should be the final step before entering into a formal agreement with the supplier. During this audit, you will assess the supplier’s compliance with industry standards, such as ISO 9001, and their ability to consistently meet your product quality requirements. This step is essential to ensure that the supplier can deliver products that meet your expectations and adhere to regulatory standards.

- Regular Audits to Ensure Continuous Improvement: In addition to audits conducted during the supplier qualification process, it is also important to schedule regular audits of your own facilities and those of your suppliers to ensure continuous improvement. These audits should be planned periodically, based on the specific needs and risks associated with each facility. Regular audits help identify areas for improvement in production processes, working conditions, and compliance with environmental and safety regulations.

- Conducting Audits During Major Operational Changes: Another key time to schedule a factory audit is when there are significant changes in your operations, such as the introduction of new production processes, the implementation of new technology, or changes in regulatory requirements. Audits during these times help ensure that the changes are implemented smoothly and that they do not negatively impact product quality, workplace safety, or compliance with industry standards.

- Post-Audit Follow-Up and Timing: Finally, it’s important to consider the timing of follow-up audits after initial audits have been conducted. Follow-up audits should be scheduled to assess the effectiveness of corrective actions taken in response to the findings of the initial audit. The timing of these audits will depend on the nature of the issues identified and the time required to implement the corrective measures.

How Is a Factory Audit Conducted?

Conducting a factory audit is a systematic process designed to assess a supplier’s facilities, management systems, and compliance with industry standards. The audit ensures that the manufacturing facility meets the necessary requirements for product quality, safety, and overall operational effectiveness. Understanding the steps involved and what to include in a factory audit checklist is essential for achieving meaningful results.

What Steps Are Involved in Conducting a Factory Audit?

The process of conducting a factory audit typically involves several key steps like preparation, on-site inspection and documentation review, each of which plays a crucial role in the overall effectiveness of the audit. These steps are:

- Preparation: Before the audit begins, it’s essential to prepare thoroughly. This includes defining the audit’s scope, selecting the audit team, and reviewing the supplier’s documentation. The audit checklist should be tailored to the specific requirements of the industry and the products being manufactured.

- On-Site Inspection: The next step involves visiting the manufacturing facility. During the facility inspection, the audit team evaluates the working conditions, manufacturing processes, quality management systems, and compliance with industry standards such as ISO 9001. The auditors also examine the production lines, employee safety protocols, and the facility’s overall capability to meet quality standards.

- Documentation Review: The audit team reviews the supplier’s documentation, including quality management systems, process controls, and records of previous audits. This step is crucial for verifying that the supplier adheres to the necessary regulations and maintains consistent product quality.

- Interviews with Key Personnel: Auditors often conduct interviews with key personnel, such as production managers, quality control staff, and other employees. These interviews provide insights into the supplier’s operational practices, management commitment, and adherence to industry standards.

- Identification of Areas for Improvement: Based on the findings from the on-site inspection and documentation review, the audit team identifies areas for improvement. This includes any non-compliance issues, gaps in the quality management system, and other areas that need attention to meet industry standards.

- Audit Report and Follow-Up: After the audit, the team compiles a detailed report outlining their findings, including both strengths and weaknesses of the facility. The report also provides recommendations for corrective actions. A follow-up audit may be scheduled to ensure that the necessary improvements have been implemented effectively.

What Should You Include in Your Factory Audit Checklist?

A well-structured factory audit checklist should be comprehensive, covering a wide range of factors that impact the supplier’s ability to deliver quality products.

Nine key areas to include in a factory audit checklist are:

- Quality Management System (QMS): Ensure that the supplier has a robust QMS in place that aligns with ISO 9001 standards. This includes reviewing documentation, process controls, and quality assurance practices.

- Compliance with Industry Standards: Check that the facility complies with relevant industry standards and regulations. This includes compliance audits for safety standards, environmental regulations, and labor laws.

- Production Processes: Evaluate the efficiency and effectiveness of the production processes. This involves inspecting the machinery, production lines, and overall workflow to ensure that they meet the required quality standards.

- Working Conditions and Employee Safety: Assess the working environment, focusing on safety protocols, employee training programs, and the overall workplace environment. This includes checking for adherence to safety standards and ensuring that employees are working under safe and fair conditions.

- Supplier Performance: Review the supplier’s track record, including their ability to meet deadlines, manage supply chains, and maintain consistent product quality. This is critical for ensuring long-term reliability and business continuity.

- Environmental Audits: Consider the facility’s compliance with environmental regulations, including waste management practices and adherence to sustainability initiatives. This is increasingly important as businesses strive to improve their environmental impact.

- Security Measures: Evaluate the security protocols in place to protect the facility and its operations. This includes physical security measures, data protection protocols, and the ability to manage risks effectively.

- Continuous Improvement Initiatives: Ensure that the supplier is committed to continuous improvement, with programs in place to regularly assess and enhance their processes, quality standards, and overall performance.

- Audit Team: Finally, make sure the audit team is well-prepared and has the necessary expertise to conduct the audit effectively. The team should be familiar with the industry, the specific products being manufactured, and the relevant standards and regulations.

What Happens During an On-Site Factory Audit?

During an on-site factory audit, the audit team visits the manufacturing facility to observe operations firsthand. This phase of the audit involves several key activities:

- Facility Inspection: The auditors conduct a thorough inspection of the manufacturing facility, examining the physical layout, production lines, and equipment. They assess whether the machinery is well-maintained and capable of meeting production demands. The workplace environment is also evaluated, with a focus on safety standards, employee working conditions, and overall cleanliness.

- Quality Control Assessment: The audit team reviews the factory’s quality control processes. This includes examining how the facility ensures product quality at each stage of production, from raw material intake to final inspection before shipment. The auditors check for adherence to industry standards, such as ISO 9001, and evaluate the effectiveness of the quality management system in place.

- Compliance Verification: The auditors verify the facility’s compliance with relevant regulations and standards. This can include environmental audits, health and safety assessments, and checks on labor practices. Compliance audits ensure that the facility is meeting all legal and industry-specific requirements.

- Supply Chain Evaluation: The audit team assesses the facility’s role within the broader supply chain. This involves reviewing supplier performance, supply chain transparency, and the facility’s ability to manage supply chain risks effectively. The goal is to ensure that the factory is a reliable part of the supply chain, capable of delivering products on time and to the required quality standards.

- Documentation Review: As part of the on-site audit, the team reviews various documents related to the factory’s operations. This includes records of previous audits, quality control logs, and compliance certificates. The documentation review helps to validate the findings from the on-site inspection and provides a deeper understanding of the facility’s management systems.

What Are Effective Techniques for Conducting Interviews and Document Reviews During Audits?

Conducting interviews and reviewing documents are critical activities that provide valuable insights into the facility’s operations and help to identify areas for improvement. Effective techniques for handling these tasks include:

- Structured Interviews: When conducting interviews, it’s important to have a structured approach. Prepare a set of questions in advance that cover key aspects of the facility’s operations, such as production processes, quality control, and compliance with standards. Interview key personnel, including production managers, quality control staff, and workers, to gain a comprehensive understanding of how the facility operates.

- Open-Ended Questions: Use open-ended questions during interviews to encourage detailed responses. This helps to uncover potential issues that may not be evident during the on-site inspection. For example, ask about any challenges faced in maintaining quality standards or managing supply chain disruptions.

- Document Sampling: Instead of reviewing every document in detail, use a sampling method to select key records for review. Focus on documents that are most relevant to the audit’s objectives, such as recent quality control logs, compliance certificates, and records of previous audits. This approach allows the audit team to efficiently verify the facility’s compliance and operational effectiveness.

- Cross-Referencing Information: Cross-reference the information gathered during interviews with the documentation reviewed. This helps to validate the accuracy of the data and ensures that the findings are consistent. For instance, if an interview reveals a potential issue with product quality, check the relevant quality control records to confirm the issue.

- Confidentiality and Sensitivity: Handle all information gathered during interviews and document reviews with confidentiality and sensitivity. This builds trust with the facility’s staff and encourages openness during the audit process. Assure the interviewees that their responses will be used to improve operations and not for punitive purposes.

- Real-Time Documentation: Take notes in real-time during interviews and document reviews. This ensures that no important details are missed and helps in compiling a comprehensive audit report later. Use these notes to highlight areas for improvement and to provide recommendations for corrective actions.

How Long Does a Factory Audit Take?

A factory audit typically takes between one to three days, depending on the size and complexity of the manufacturing facility. The duration can vary based on factors such as the number of production lines, the scope of the audit, and the thoroughness required to assess compliance with quality management systems and supply chain standards.

A more detailed factory audit, particularly one involving multiple types of audits like compliance audits or capability audits, may extend beyond this timeframe to ensure all critical aspects are thoroughly evaluated.

How Long Does It Take to Get Audit Results?

The timeline for receiving audit results typically ranges from a few days to a couple of weeks, depending on the complexity of the audit and the processes involved in compiling the report. In most cases, preliminary findings are shared with the factory management at the end of the on-site audit, with the full report delivered shortly after. This allows you to start planning for any necessary improvements as soon as possible, ensuring that your supply chain remains compliant and efficient.

What Should Be Done After a Factory Audit?

After completing a factory audit, there are six important steps to ensure continuous improvement and compliance with industry standards:

- Begin by reviewing the audit report in detail. This report will outline areas for improvement, highlight any non-compliance issues, and provide an overall assessment of the manufacturing facility’s performance. It’s essential to prioritize actions based on the findings, focusing first on any critical compliance issues that could affect product quality or supply chain reliability.

- Collaborate with your suppliers and internal teams to develop an action plan addressing the identified gaps. This plan should include specific steps, timelines, and responsible parties for each improvement area.

- Regular follow-up audits or inspections are recommended to ensure that the corrective actions are implemented effectively and that improvements are sustained over time.

- Update your factory audit checklist based on the latest audit findings. This helps in refining the criteria for future audits and ensures that all critical areas are consistently evaluated.

- Continuous training programs for your audit team and suppliers can also help in maintaining high standards and reducing the risk of non-compliance in future audits.

- Ensure that all stakeholders, including management, suppliers, and relevant teams, are informed about the audit outcomes and the subsequent actions. Clear communication fosters accountability and supports the overall goal of achieving and maintaining high-quality standards across the supply chain.

How Should Audit Findings Be Analyzed and Acted Upon?

Analyzing audit findings involves a systematic approach to interpreting the data and identifying root causes of any issues. Start by categorizing the findings based on their impact on product quality, compliance with industry standards, and overall business operations.

High-priority issues, such as those affecting customer satisfaction or safety, should be addressed first. Once the findings are categorized, involve key stakeholders in a decision-making process to develop corrective actions. These actions should be specific, measurable, and time-bound, ensuring that each issue is effectively resolved.

For example, if a factory audit reveals gaps in quality control processes, you might need to implement additional training programs for staff or revise existing procedures to ensure compliance with quality management systems.

When and How Follow-Up Audits Should Be Scheduled?

Follow-up audits are an integral part of ensuring that the corrective actions taken after a factory audit are effective and sustainable. The timing of these audits depends on the severity of the findings and the complexity of the corrective measures.

For critical issues that could impact product quality or compliance, a follow-up audit should be scheduled within a few months to verify that the necessary improvements have been implemented. When planning follow-up audits, consider the specific areas that require re-evaluation.

Focus on the most significant findings from the initial audit, such as non-compliance with safety standards or gaps in the quality management system.

The follow-up audit should assess whether the corrective actions have effectively addressed these issues and whether further improvements are needed. To efficiently schedule follow-up audits, coordinate with the factory management and audit team to ensure that all necessary resources are available.

It’s also important to keep the factory informed about the upcoming audit, allowing them to prepare and ensure that all relevant documentation and processes are ready for review. Regularly scheduled follow-up audits, even after issues have been resolved, can help maintain high standards within the manufacturing facility and ensure continuous improvement in the supply chain.

How Do You Prepare for a Successful Factory Audit?

Preparing for a successful factory audit requires a well-structured approach to ensure that all aspects of your manufacturing facility meet industry standards. Here are our five tips on how to prepare for it:

- The first step is to familiarize yourself with the specific requirements of the audit, whether it’s a compliance audit, an environmental audit, or a quality management systems audit. Understanding these requirements will help you focus on the critical areas that the auditors will examine.

- Start by conducting an internal audit using a factory audit checklist tailored to the type of audit you are expecting. This will allow you to identify any gaps in your processes, such as non-compliance with ISO 9001 standards, and take corrective actions before the actual audit.

- Make sure to involve all relevant departments, including quality control, production processes, and supply chain management, to ensure a comprehensive review. Documentation is another key area.

- Ensure that all necessary documents, such as standard operating procedures, training records, and compliance certifications, are up to date and easily accessible. This not only helps the audit process run smoothly but also demonstrates your organization’s commitment to maintaining high standards.

- Training your team on what to expect during the audit can also significantly contribute to its success. This includes preparing them to answer questions from the audit team confidently and accurately. Regular training programs on quality management and safety standards can help maintain continuous improvement in your operations, making the audit process less stressful and more efficient.

What Common Mistakes Occur During Audit Preparation and How Can They Be Avoided?

One of the most common mistakes during audit preparation is failing to conduct a thorough internal audit. Skipping this step can leave significant issues unnoticed, which could result in findings during the actual audit. To avoid this, always perform a detailed internal audit well in advance, covering all areas that the external auditors will examine.

Another frequent mistake is inadequate documentation. Missing or outdated documents can slow down the audit process and raise questions about your management system’s effectiveness. To prevent this, create a systematic approach to document management, ensuring that all records are regularly updated and easily retrievable.

Overlooking the importance of employee preparation is another pitfall. Employees who are not well-prepared may provide incomplete or inaccurate information during the audit. To avoid this, conduct training sessions that cover the audit process and specific roles each team member will play. This will help ensure that your staff is confident and knowledgeable when interacting with the auditors.

Lastly, not addressing known issues before the audit can be a critical error. If there are areas for improvement that you are aware of, take action to resolve them before the audit. Proactive problem-solving demonstrates your commitment to quality and can significantly impact the audit’s outcome.

What Are the Common Challenges in Factory Auditing and How to Overcome Them?

Factory audits are essential for ensuring that your supply chain operates efficiently and meets quality standards. However, they come with challenges that can hinder the process. Here are some common hurdles and strategies to overcome them.

- Limited Access to Information: During a factory audit, auditors might encounter restricted access to critical data, such as production records or management system documents. This can be due to supplier reluctance or poor record-keeping. To overcome this, you should establish clear communication with your suppliers before the audit. Ensure they understand the importance of transparency and are prepared to provide all necessary documentation.

- Inadequate Preparation by the Supplier: Suppliers may not always be fully prepared for an audit, leading to delays and incomplete assessments. To address this, provide your suppliers with a detailed factory audit checklist well in advance. This checklist should include all the requirements for the audit, such as documents needed, areas to be inspected, and any specific production processes to be reviewed.

- Language and Cultural Barriers: Auditors often face challenges when working in international environments where language and cultural differences can create misunderstandings. To mitigate these issues, consider hiring local auditors who are familiar with the regional language and customs. This approach helps in more effective communication and a better understanding of the workplace environment.

- Resistance to Change: Some suppliers may resist implementing changes suggested during the audit, especially if these changes involve significant modifications to their manufacturing processes or quality control systems. To overcome this, focus on continuous improvement by highlighting the long-term benefits of the changes, such as enhanced product quality, compliance with industry standards, and potential cost savings.

- Time Constraints: Conducting factory audits within a limited timeframe can lead to rushed evaluations and overlooked areas for improvement. To manage this challenge, ensure that your audit team is well-prepared and organized. Plan the audit schedule meticulously, allowing sufficient time for each step, including interviews, document reviews, and on-site inspections.

- Inconsistent Audit Practices: When conducting multiple audits across different suppliers, inconsistencies in audit practices can lead to varying results. Standardize your audit process by training your audit team on a uniform set of procedures and criteria. This standardization ensures that all audits are conducted with the same level of rigor and that findings are comparable across different suppliers.

How Do Factory Audits Ensure Compliance with International Standards and Frameworks?

Factory audits assess the effectiveness of a company’s quality management system and help identify areas for improvement. By evaluating the processes, practices, and procedures within a manufacturing facility, factory audits ensure that products meet customer expectations and industry standards.

ISO 9001 is a widely recognized standard that sets the criteria for quality management systems. Companies that adhere to ISO 9001 demonstrate their commitment to maintaining high product quality and continuous improvement. Audits conducted under this framework assess whether the manufacturing processes comply with the required quality management system, ensuring that products meet customer and regulatory requirements.

Also, several other regulations govern factory audits depending on the industry and region. For example, the Consumer Product Safety Improvement Act (CPSIA) in the United States requires that certain products, especially those intended for children, undergo rigorous safety testing and compliance audits.

Similarly, the European Union’s General Data Protection Regulation (GDPR) mandates that companies handling personal data adhere to strict data protection standards, which may also be assessed during audits.

Factory Audit Based on ISO 9001

Adhering to the principles of ISO 9001, factory audits help organizations ensure that they are not only compliant with international standards but also positioned to deliver high-quality products consistently.

- Customer Focus: One of the key principles of ISO 9001 is customer focus. Organizations must understand their customers’ needs and expectations to deliver products and services that meet or exceed these requirements. A factory audit assesses whether the supplier prioritizes customer satisfaction and implements practices that align with this focus.

- Leadership: Effective leadership is essential for establishing a quality-driven culture within an organization. ISO 9001 emphasizes the importance of clear vision, mission, and values. During a factory audit, auditors evaluate the leadership’s role in fostering a commitment to quality and continuous improvement across all levels of the organization.

- Engagement of People: Employee engagement is vital for the success of any quality management system. Audits based on ISO 9001 assess how well an organization engages and empowers its employees to contribute to quality improvement initiatives. This includes training programs and initiatives that encourage active participation from all staff members.

- Process Approach: A process-based approach to quality management ensures that processes are designed, implemented, and continually improved to achieve the desired results. Factory audits evaluate whether the organization has established clear and efficient processes that align with ISO 9001 standards. This approach helps in identifying inefficiencies and implementing corrective actions.

- Improvement: Continuous improvement is a fundamental aspect of ISO 9001. Organizations must strive to enhance their performance by identifying and addressing areas for improvement. Factory audits assess the organization’s commitment to continual improvement by reviewing past performance, identifying trends, and recommending actions for future enhancement.

- Evidence-Based Decision Making: Decisions within an organization should be based on objective data and evidence rather than intuition. ISO 9001 encourages evidence-based decision-making. During a factory audit, auditors review the organization’s data collection and analysis processes to ensure that decisions are made using reliable and accurate information.

- Relationship Management: ISO 9001 emphasizes the importance of managing relationships with suppliers, customers, and other stakeholders to achieve mutual benefits. Factory audits evaluate how well the organization maintains these relationships and ensures that suppliers adhere to quality standards, thereby strengthening the overall supply chain.

What Is the Role of Third-Party Auditors in Factory Audits?

Third-party auditors play an essential role in conducting factory audits, providing an objective and unbiased assessment of a facility’s compliance with industry standards, regulations, and customer requirements. By leveraging their expertise, third-party auditors help companies identify potential issues within their supply chain and ensure that their products meet the required quality standards.

Third-party auditors are responsible for thoroughly inspecting the manufacturing processes, working conditions, and overall management systems within a facility. Their role involves examining every aspect of the production processes, from raw material procurement to final product delivery.

By doing so, they ensure that suppliers adhere to quality control measures, comply with safety standards, and operate in line with environmental regulations.

Additionally, third-party auditors provide valuable insights into areas for improvement. They offer recommendations that can help suppliers enhance their operational efficiency, reduce risks, and maintain high levels of product quality. This external perspective is crucial in helping businesses achieve continuous improvement and ensure compliance across their supply chains.

How to Schedule a Factory Audit?

A well-timed and properly planned audit can identify potential risks, areas for improvement, and help maintain strong relationships with suppliers. Here’s a guide on how to schedule a factory audit effectively.

- Determine the Type of Audit Required Before scheduling, you need to understand the type of factory audit that best suits your needs. Common types include compliance audits, environmental audits, and capability audits. Each serves a different purpose, whether it’s to ensure adherence to industry standards like ISO 9001, assess the workplace environment, or evaluate the manufacturing processes. Understanding the specific requirements of your business will help you choose the right audit type.

- Select a Suitable Time Timing is crucial when scheduling a factory audit. Consider the production cycles of your supplier or manufacturing facility. Conducting factory audits during peak production times might give a more accurate picture of the operational capacity but could also disrupt operations. On the other hand, auditing during slower periods may not reveal all potential issues. Balance the need for thoroughness with the operational realities of your supplier.

- Coordinate with the Audit Team Once the timing is determined, coordinate with your audit team. This could include internal auditors, third-party auditors, or a combination of both. Make sure the audit team is briefed on the specific areas of focus, such as product quality, working conditions, and adherence to quality control measures. Effective coordination ensures that all aspects of the audit are covered comprehensively.

- Notify the Supplier Inform the supplier or the manufacturing facility about the upcoming audit well in advance. This allows them to prepare and ensure that all necessary documentation, such as the factory audit checklist and compliance records, are readily available. Transparency with your supplier helps in maintaining a collaborative relationship, ensuring that the audit process is smooth and productive.

- Prepare the Necessary Documentation Before the audit, gather all relevant documents and information, including previous audit reports, production processes, and quality management system records. This preparation helps the audit team to understand the context and focus on areas that need improvement. Having a well-organized set of documents also speeds up the audit process, making it more efficient.

- Plan for Post-Audit Actions Scheduling a factory audit doesn’t end with the audit itself. You need to plan for the post-audit actions. This includes reviewing the audit findings, implementing necessary changes, and scheduling follow-up audits if required. Continuous improvement is a key aspect of factory audits, and planning ahead ensures that the audit results lead to meaningful actions.

Schedule a Factory Audit with QCADVISOR

How Can Technology Enhance Factory Audit Processes?

The integration of advanced tools and software into auditing procedures allows for better data collection, analysis, and reporting, ensuring that audits are more thorough and actionable. By leveraging technology, you can enhance the transparency and effectiveness of factory audits, which ultimately leads to improved product quality and stronger supply chain management.

What Are the Latest Technological Advances in Factory Auditing?

Recent advancements in technology have introduced a variety of tools that are revolutionizing factory audits. These tools range from specialized audit management software to devices that improve data accuracy and accessibility.

- Audit Management Software: Modern audit management systems streamline the entire auditing process, from planning to execution. These platforms allow auditors to create and manage factory audit checklists, document findings, and generate reports in real time. By automating routine tasks, this software reduces human error and ensures consistency across different types of factory audits.

- Mobile Applications: Mobile apps designed for factory audits enable auditors to collect data on-site using tablets or smartphones. These apps often include features like barcode scanning, photo documentation, and GPS tagging, which help auditors capture detailed information about the manufacturing facility and its processes. This data can be synchronized with audit management software, allowing for seamless integration and analysis.

- Data Analytics and AI: The use of data analytics and artificial intelligence (AI) in factory audits is growing. These technologies help auditors analyze large volumes of data to identify trends, patterns, and areas for improvement. AI can also assist in predictive analysis, enabling companies to anticipate and address potential issues before they become significant problems. This proactive approach supports continuous improvement and ensures compliance with quality standards.

- Blockchain for Supply Chain Transparency: Blockchain technology is gaining traction in factory audits, particularly for supply chain transparency. By using blockchain, companies can create an immutable record of each transaction and process within the supply chain. This transparency helps verify the integrity of suppliers, ensuring that they meet compliance audits and quality management systems like ISO 9001.

- IoT Devices: The Internet of Things (IoT) is another technological advancement making its way into factory audits. IoT devices can monitor various aspects of the production processes in real-time, such as temperature, humidity, and equipment performance. This real-time data is crucial for maintaining quality control and ensuring that the manufacturing facility operates within industry standards.

How Do Factory Audits Differ from Quality Inspections?

While factory audits and quality inspections are both essential tools for ensuring product quality and compliance, they serve different purposes and focus on distinct aspects of the manufacturing process.

Factory audits are comprehensive assessments that evaluate the overall capabilities and compliance of a manufacturing facility. They examine a wide range of factors, including the effectiveness of the quality management system, compliance with industry standards like ISO 9001, working conditions, and the facility’s ability to consistently produce high-quality products. Factory audits are typically conducted periodically and are more strategic in nature, providing insights into the long-term reliability and ethical practices of a supplier.

On the other hand, quality inspections are more focused and operational. They involve checking specific batches of products to ensure that they meet predefined quality standards. Quality inspections are usually conducted at various stages of the production process, such as during raw material intake, in-process production, and final product inspection before shipping. The primary goal of quality inspections is to identify and address product defects or non-compliance with customer specifications.

Factory audits are an essential part of maintaining a robust supply chain and ensuring that all aspects of production meet the required quality standards. By carefully scheduling and preparing for a factory audit, you can identify areas for improvement, enhance product quality, and strengthen your relationships with suppliers.

Remember that the success of a factory audit lies not just in the audit itself but in the subsequent actions you take based on the findings.

Whether you are conducting a factory audit to assess compliance, improve working conditions, or ensure product quality, the key is in the details—selecting the right type of audit, coordinating with the right team, and planning for both the audit and the follow-up actions. With these steps, you can ensure that your audits are not just a formality, but a valuable tool for continuous improvement and sustained success in your industry.

Frequently Asked Questions

1. What if You Fail an Audit?

If you fail a factory audit, it’s crucial to address the identified issues promptly. Start by reviewing the audit report to understand areas of non-compliance. Develop a corrective action plan targeting specific gaps, whether in product quality, working conditions, or compliance with industry standards. Communicate with the auditor to ensure your corrective actions align with the requirements and prepare for a follow-up audit.

2. Is a Factory Audit Hard to Pass?

Passing a factory audit can be challenging, but preparation is key. Regular internal audits and maintaining up-to-date documentation are essential for meeting quality standards. The difficulty varies depending on the type of audit and your adherence to industry standards, such as ISO 9001. Thorough preparation, continuous improvement, and strong supplier management can significantly increase your chances of passing the audit successfully.